Industrial

innovation

Driven by quality, designed for performance

Meet us at Wire Düsseldorf 2026!

From design to production

At DCS Machines, we find solutions

Any technical problem can be solved through design and creative engineering. We specialize in finding the solutions that are best fit to solve our clients’ problems.

Our services

Industrial design and production

We design and manufacture industrial machinery, systems and sub-systems.

Mechanically welded parts and structures

We specialize in mechanically welded parts and structures for any application.

Customized industrial consultancy

We understand industry and know how to plan complex production systems.

The wire industry

We are revolutionizing the wire industry

We have deep knowledge about wire drawing machines. We know how they work, we understand how they are built. So we made them better. Smaller. Faster. Cleaner. We are turning the industry on its head.

Our products

Wire drawing machines

MWM370 Mark 2 is the latest DCS wire drawing machine. It was designed based on a modular concept that allowed for a smaller footprint, increased efficiency and hassle-free operation.

Steel fiber machines

The experience we have gained from collaborating with manufacturers within wire industry is reflected in our steel fiber machines.

Packaging systems

We developed solutions that specifically address the challenges our clients face during packaging and feeding steel reinforcement fibers.

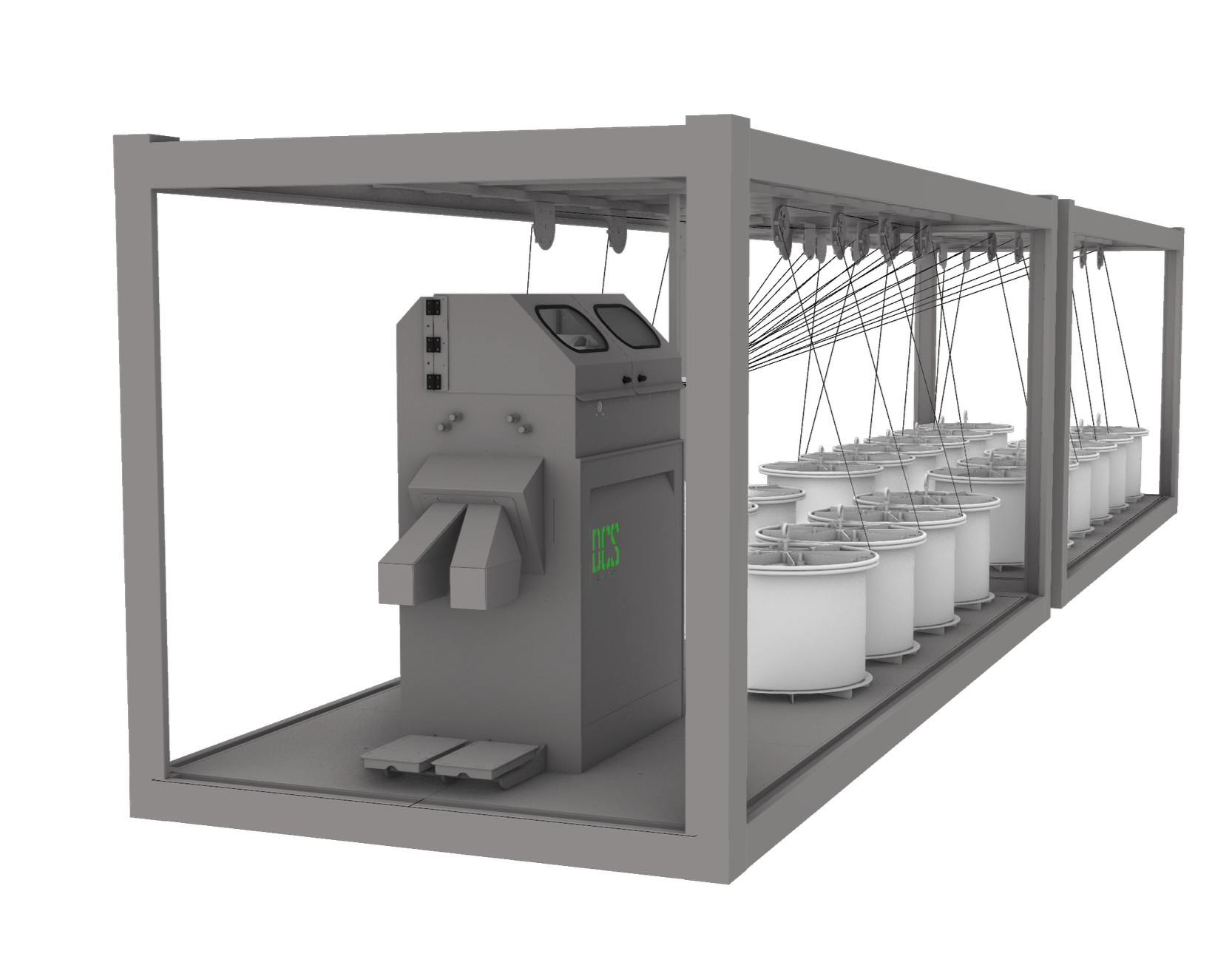

MOBS 4

Mark 1

Having faced the toughest industrial conditions, the MOBS 4 Mark 1 steel fibers machines has proven its efficiency and resilience through:

top industrial productivity

highest operator safety standards

lowest dust emissions

highest level of quality and precision

maximum quality and consistency of the steel fibers

lowest possible downtime

ease of machines operation, maintenance and cleaning

ability to adjust fast, easy and precise to any type of fibers

modular design

lowest possible fiber production cost

fast ROI

ability to produce on-site (container module option )

reduced maintenance and spare parts costs

multiple packaging option available (paper bags, big-bags, cardboard boxes)

MWM370

Mark 2

Modular wire drawing machine

plug-and-play concept: no need for special installation training or set-up. Just place the machine on the factory floor, connect to power and water and start drawing wire. From delivery to wire drawing in under 24h.

compact design: required factory floor area reduced by 75% compared to conventional wire drawing machines. Back-to-back configuration with frontal access to all components.

modular design: the number of installed capstans/modules can be adjusted based on production requirements, even after the initial machine configuration

ergonomic design: the MWM370 is designed to be easily operated and maintained by one person.

high performance: high speed, fast acceleration and deceleration rates, continuous speed adjustment to compensate for die wear

high efficiency: minimum water consumption, minimal running and maintenance costs, no compressed air requirement, reduced energy cost by up to 15%; possibility to bypass certain capstans if a smaller number of drafts is required, saving even more energy.

full automation: automatic process monitoring (e.g. water temperature and level sensors); linear output dancer control; ultra fast machine stop in case of wire breakage; auto-calibration startup procedure; no manual parametrization required

stops in less than 1 second from any speed and without any wire breakage